VMC850B CNC Milling machine, iziko umatshini nkqo

Iimpawu zeMveliso

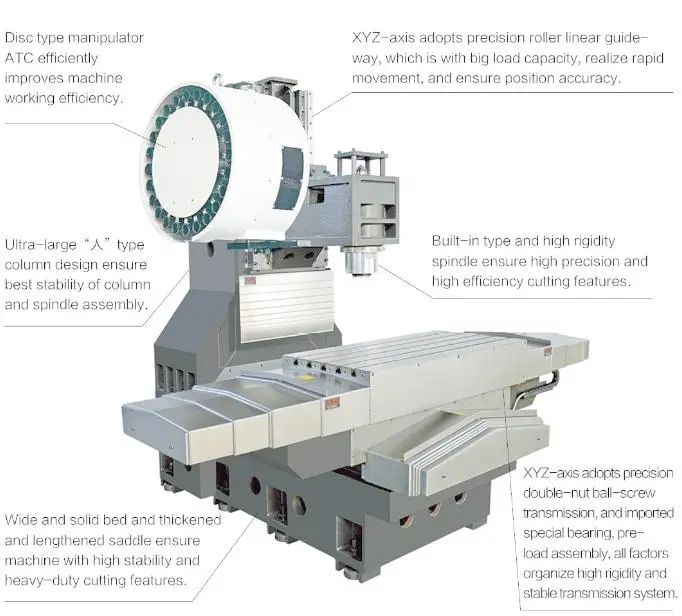

1.Umyalelo jikelele

Lo matshini uyilwe ngobeko lwesakhelo esithe nkqo. Ikholamu ixhonywe kumzimba womatshini, izilayidi zebhokisi ye-spindle kwikholamu eyenza intshukumo ye-axis ye-Z, izilayidi zesali kumatshini wokwenza intshukumo ye-Y axis, izilayidi eziSebenzayo kwisali zenza i-X axis motion. Amazembe amathathu onke angumkhombandlela onesantya esiphezulu sokutya kunye nokuchaneka okuphezulu. Sisebenzisa umgangatho ophezulu we-grey cast iron kumzimba womatshini, ikholomu, isali, i-worktable, ibhokisi ye-spindle ene-resin sand technology kunye namaxesha ama-2 onyango lokuguga ukuphelisa uxinzelelo lwangaphakathi olushiyekileyo lwezinto. Ezi nxalenye zonke ziphuculwe yiSolidWorks software, ephucula kakhulu ukuqina kunye nozinzo kungekuphela nje kula malungu kodwa umatshini. Kwakhona iya kuthintela i-deformation kunye ne-vibration ebangelwa ukusika. Amacandelo abalulekileyo onke angeniswe kwi-brand eyaziwayo yehlabathi ukwenza umatshini uzinzo oluphezulu kunye nokuqina. Lo matshini unokufezekisa inkqubo yokugaya, ukugaya, ukubuyisela kwakhona, ukudinwa, ukuhlaziya, ukucofa kwaye ngokuqhelekileyo kusetyenziselwa i-Military, imigodi, i-automotive, i-mold, i-instrumentation kunye namanye amashishini okulungisa oomatshini. Ingasetyenziselwa zonke iintlobo zokuchaneka okuphezulu kunye neemodeli ezininzi zenkqubo. Ilungile kwimveliso encinci kunye nephakathi, imveliso eyahlukeneyo, ingafaka kumgca wemveliso ozenzekelayo.

2.Inkqubo yamazembe amathathu

Amazembe amathathu onke angumkhombandlela kunye noyilo olukhulu lwespan lokuchaneka okuhlala ixesha elide. Iinjini zee-axes ezi-3 ziqhagamshelwe ngokuthe ngqo kunye nesikrufu sebhola esichanekileyo ngaphandle kwe-gap flexible coupling. Ibhola nganye isikrufu se-axes ezi-3 ithathwa ngaphandle ukusuka kwi-angular echanekileyo yebhola edibeneyo kunye neebheringi zobuchwephesha ezihambelanayo, kwakhona siya kwenza i-pre-tension ye-screws yebhola ukuchaneka okuphezulu kunye nokuchaneka.I-Z-axis servo motor inomsebenzi wokuqhawula okuzenzekelayo. Kwimeko yokungaphumeleli kwamandla, i-motor brake ingabanjelwa ngokuzenzekelayo yi-brake ukukhusela ukuba ijikeleze, edlala indima ekukhuseleni ukhuseleko.

3.Iyunithi yokuphotha

I-Spindle iveliswa ngumenzi oyingcali ukuqinisekisa ukuchaneka okuphezulu kunye nokuqina. Ukuthwala i-Spindle kuphuma kwi-brand eyaziwayo yehlabathi ephezulu echanekileyo, kwaye idityaniswe kwimeko yobushushu obungaguqukiyo kwaye akukho luthuli. Emva koko, zonke ii-spindles ziyakwenza uvavanyo lwe-dynamic balance ukuqinisekisa ukuba ubude bobomi kunye nokuthembeka. Ixhotyiswe ngenkqubo yokukhusela umjikelo womoya woxinzelelo oluphantsi, ivuthela umoya ophantsi woxinzelelo kwisithuba esingaphakathi esijikelezayo senza umaleko wokhuselo lomoya ukunqanda uthuli, ukuphola. umsonto wokusonta. Kule meko, ukuthwala intambo yokusonta kuya kusebenza phantsi kokungangcoliseki kwemekobume, nto leyo eya kukhusela iyunithi yokusonta kunye nobomi obude bokusonta. Isantya somjikelo asinakutshintshwa ngaphakathi koluhlu lwesantya sokusonta, olulawulwa yimoto yangaphakathi encode ukuba ibe nomsebenzi wokujongwa kokujikeleza kunye nokucofa okuqinileyo.

4.Inkqubo yokutshintsha isixhobo

Umthamo wemagazini yesixhobo esiqhelekileyo salo matshini yi-24T kwaye ihlanganiswe kwikholamu yecala. Xa itshintsha isixhobo, isixhobo sokuqhuba ipleyiti kwaye ibekwe ngemoto drive hobbing cam mechanism, emva kokuba i-spindle ifike kwindawo yokutshintsha isixhobo, i-ATC iya kufezekisa utshintsho lwesixhobo kwaye ithumele isenzo sesixhobo. I-ATC yindlela yokwenza i-hobbing cam kwaye yenza uxinezeleko lwangaphambili emva koko inokujikeleza ngesantya esiphezulu, okona kungcono kutshintsho olukhawulezayo noluchanekileyo lwesixhobo.

5.Inkqubo epholileyo

Umatshini uxhotyiswe ngempompo enkulu yokuntywila emanzi kunye netanki enkulu yamanzi. Isantya sempompo yokupholisa yi-2m³/h ukuqinisekisa ukuba kukho ukupholisa okwaneleyo. Kukho umbhobho wokupholisa kumphezulu webhokisi yokusonta, onokwenza ukuba umoya uphole kwaye upholise amanzi kwisixhobo kunye neziqwenga zokusebenza. Ixhotyiswe ngompu womoya ukucoca umatshini kunye neziqwenga zokusebenza.

6.Inkqubo yomoya

Iyunithi ye-pneumatic inokucoca ukungcola kunye nokufuma kumthombo wegesi ukuphepha umonakalo kunye nokukhukuliseka kwamalungu omatshini. Iyunithi yevalve ye-Solenoid ilawula inkqubo nge-PLC ukuqinisekisa ukuba iintshukumo zesixhobo sokugoba sokuphotha, ukuvuthela kwiziko lokuphotha, isixhobo sokugoba sokuphotha kunye nokupholisa umoya okuphotha kungenziwa ngokukhawuleza nangokuchanekileyo. Ngalo lonke ixesha isixhobo sokutshintsha i-spindle, umoya ocinezelekileyo ocacileyo uya kuvuthuza usuka kwiziko lokuphotha ukucoca umngxuma ongaphakathi wokusonta kunye ne-shank yesixhobo sokuqina okuphezulu kokudityaniswa kunye nesixhobo sokusonta. Iyakwandisa ubude bobomi bokusonta.

7.Ukhuseleko lomatshini

Sisebenzisa isikhuseli sokhuseleko esisemgangathweni kumatshini, ongenakukhusela kuphela i-splash epholileyo kodwa umsebenzi wokhuseleko. Zonke izikhokelo zixhotyiswe ngekhusi lokukhusela ukunqanda ukupholisa kunye neqhekeza lokusika kwindawo engaphakathi kunye nokunciphisa ukunxitywa kunye nokhukuliseko lwesikhokelo kunye nebhola.

8.Inkqubo yokuthambisa

Isikhokelo kunye nesikrufu sebhola zixhotyiswe ngenkqubo yokuthambisa esembindini kunye nesahluli se-oyile yevolumetric kwindawo nganye, enokubonelela nge-oyile ngokwemiyinge emiselweyo kunye namaxesha okuqinisekisa ukuba ubuso besilayidi ngasinye buthanjisiwe kwaye buyilwe elisezantsi. Iyakuphucula ukuchaneka kunye nobomi obude be-ball screw kunye nesikhokelo.

9.Chip inkqubo yokuhambisa

Sinikezela ngesixhobo esisezantsi se-chip remover esisebenza ngokulula. Kwakhona unokukhetha isikhonkwane sohlobo lwe-chip conveyor okanye uhlobo lwehinge.

| Into | Iyunithi | VMC640L | I-VMC640LH | VMC850L | VMC1000L |

| Itafile yokusebenza | |||||

| Ubungakanani obusebenzayo | mm | 400×900 | 400×900 | 500×1000 | 500×1200 |

| T-slot (N×W×D) | mm | 3×18×100 | 3×18×100 | 5×18×100 | 5×18×100 |

| Ukuhamba | |||||

| X ukuhamba kwe-axis | mm | 640 | 640 | 850 | 1000 |

| Y uhambo lwe-axis | mm | 400 | 400 | 500 | 500 |

| Z uhambo lwe-axis | mm | 400 | 500 | 600 | 600 |

| Uluhlu lomatshini | |||||

| Umgama ukusuka kumbindi we-spindle ukuya kwikholamu ngaphambili | mm | 440 | 476 | 572 | 572 |

| Umgama ukusuka ekupheleni kwespindle ukuya kwitafile yomsebenzi | mm | 120-520 | 120-620 | 120-720 | 120-720 |

| Ubungakanani bomatshini | |||||

| L×W×H | mm | 2200×2100×2500 | 2200×2100×2550 | 2540×2320×2780 | 3080×2320×2780 |

| Ubunzima bomatshini | |||||

| Max. ukuthwala umthwalo wetafile yokusebenza | kg | 350 | 350 | 500 | 600 |

| Ubunzima bomatshini | kg | 3900 | 4100 | 5200 | 5600 |

| I-spindle | |||||

| Umngxuma we-spindle taper | BT40 | BT40 | BT40 | BT40 | |

| Amandla e-spindle | kw | 5.5 | 5.5 | 7.5/11 | 7.5/11 |

| Max. isantya sokusonta | rpm | 8000/10000 | 8000/10000 | 8000/10000 | 8000/10000 |

| Ukutya(ngqo qhuba) | |||||

| Max. isantya feed | Mm/umz | 10000 | 12000 | 12000 | 12000 |

| Isantya sesondlo esikhawulezayo (X/Y/Z) | m/umz | 20/20/10 | 30/30/24 | 32/32/30 | 32/32/30 |

| Isikrufu sebhola (ububanzi + ilothe) | |||||

| Isikrufu sebhola ye-X ye-axis | 3210 | 3212 | 4016 | 4016 | |

| Y isikrufu sebhola e-axis | 3210 | 3212 | 4016 | 4016 | |

| Z isikrufu sebhola e-axis | 3210 | 4012 | 4016 | 4016 | |

| Isixhobo seMagazini | |||||

| Umthamo wemagazini yesixhobo | T | 16 | 16 | 24 | 24 |

| Ixesha lokutshintsha isixhobo | s | 2.5 | 2.5 | 2.5 | 2.5 |

| Ukuchaneka kokuma (umgangatho weSizwe) | |||||

| Ukubekwa kokuchaneka (X/Y/Z) | mm | 0.008 | 0.008 | 0.008 | 0.008 |

| Ukumisa kwakhona ukuchaneka(X/Y/Z) | mm | 0.005 | 0.005 | 0.005 | 0.005 |

| HAYI. | Igama | Uphawu |

| 1 | Inkqubo ye-CNC | Seimens 808D SYSTEM |

| 2 | Injini engundoqo | Iseti epheleleyo ye-Siemens drive kuquka i-servo motor |

| 3 | X/Y/Z i-axis motor, umqhubi | Iisimens |

| 4 | I-Ballscrew | I-Hiwin okanye i-PMI (eTaiwan) |

| 5 | Ukuthwala i-ballscrew | I-NSK (eJapan) |

| 6 | Izikhokelo zomgca | I-Hiwin okanye i-PMI (eTaiwan) |

| 7 | Injini yokuphotha | IPOSA/ROYAL (eTaiwan) |

| 8 | Umtshintshi wobushushu | ITaipin/Tongfei (Ilinge elidibeneyo) |

| 9 | Amacandelo aphambili enkqubo yokuthambisa | Proton (Ilinge elidityanelweyo) |

| 10 | Amacandelo aphambili enkqubo yomoya | AirTAC (Taiwan) |

| 11 | Iinxalenye eziphambili zenkqubo yombane | Schneider (eFransi) |

| 12 | Impompo yamanzi | eTshayina |